Robotic grippers

With Actuation Mode Switching

A Joint-Selective Robotic Gripper

with Actuation Mode Switching

Concept Design System Requirements

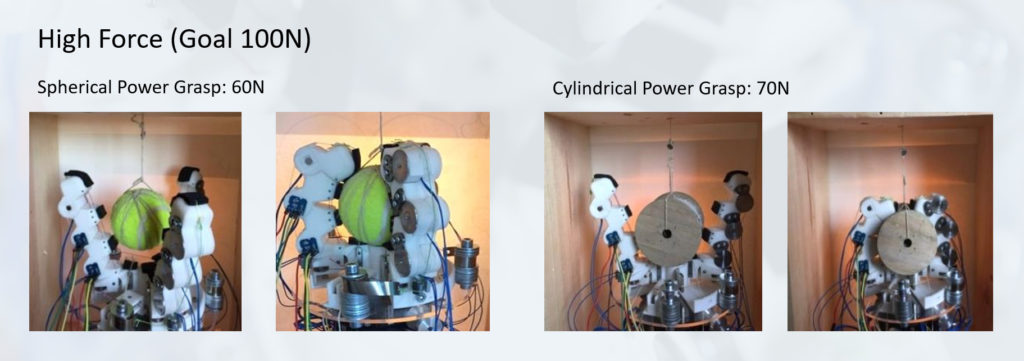

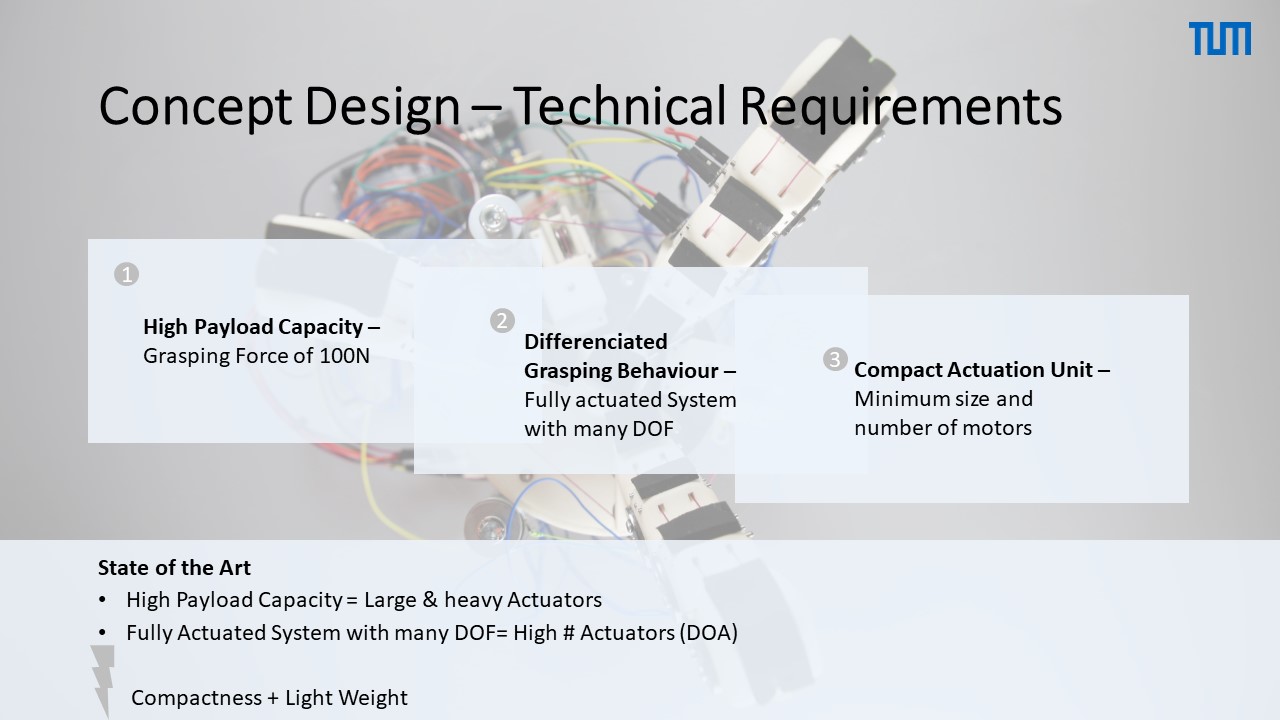

High Payload Capacity –Grasping things of a weight comparable to a beer case. Grasping Force of 100N.

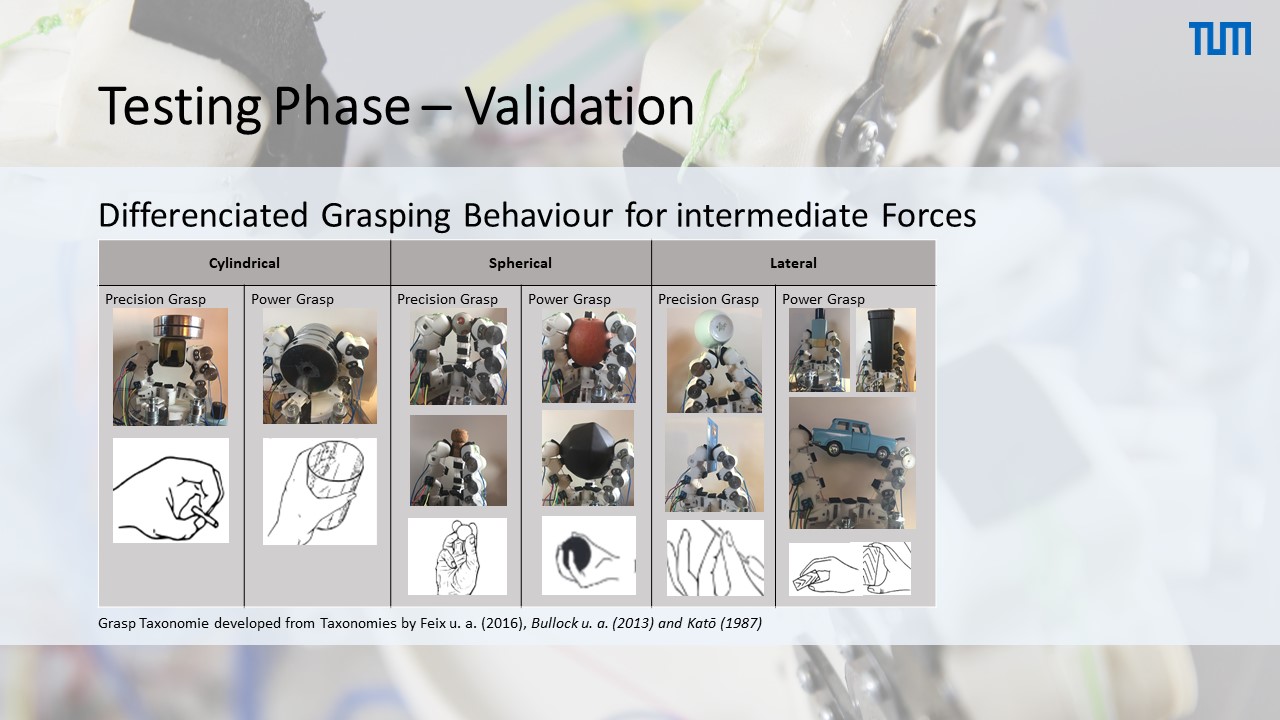

Differentiated Grasping Behaviour – Moderate dexterity. Fully actuated System with many DOF.

Compact Actuation Unit for end effector design. Minimum size and number of motors.

ROBOT GRIPPERS

high accuracy and dexterity

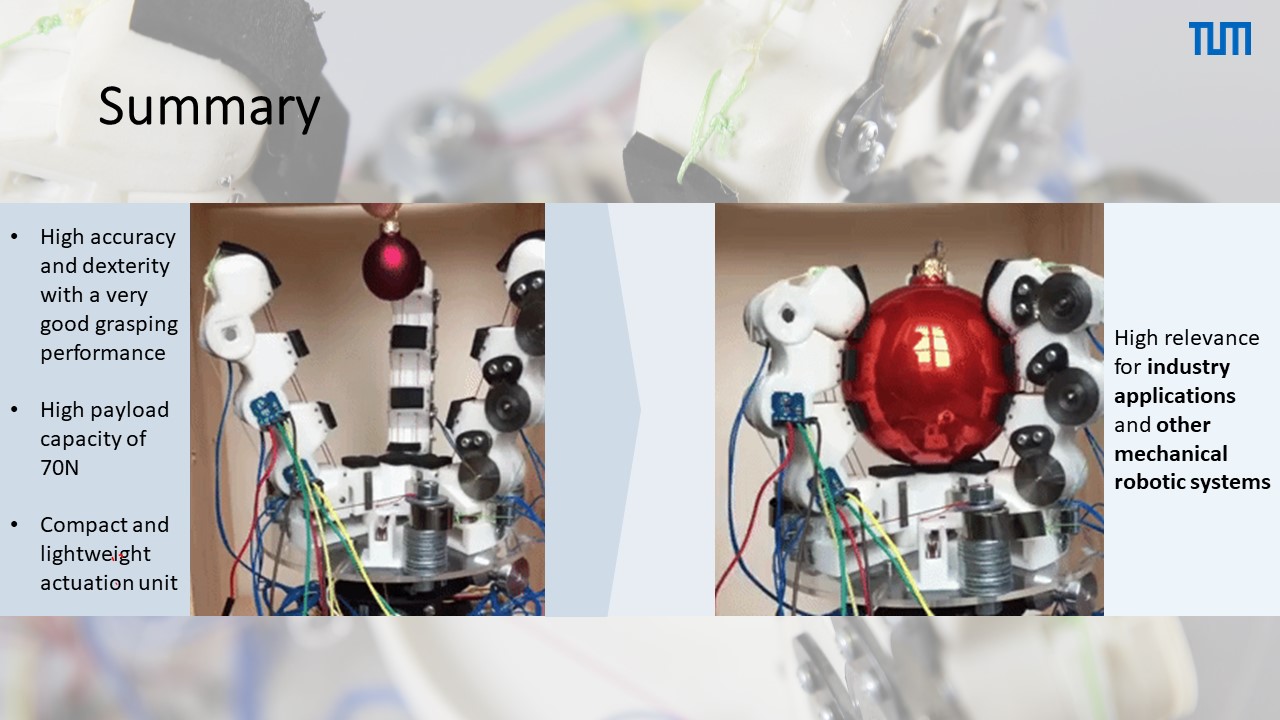

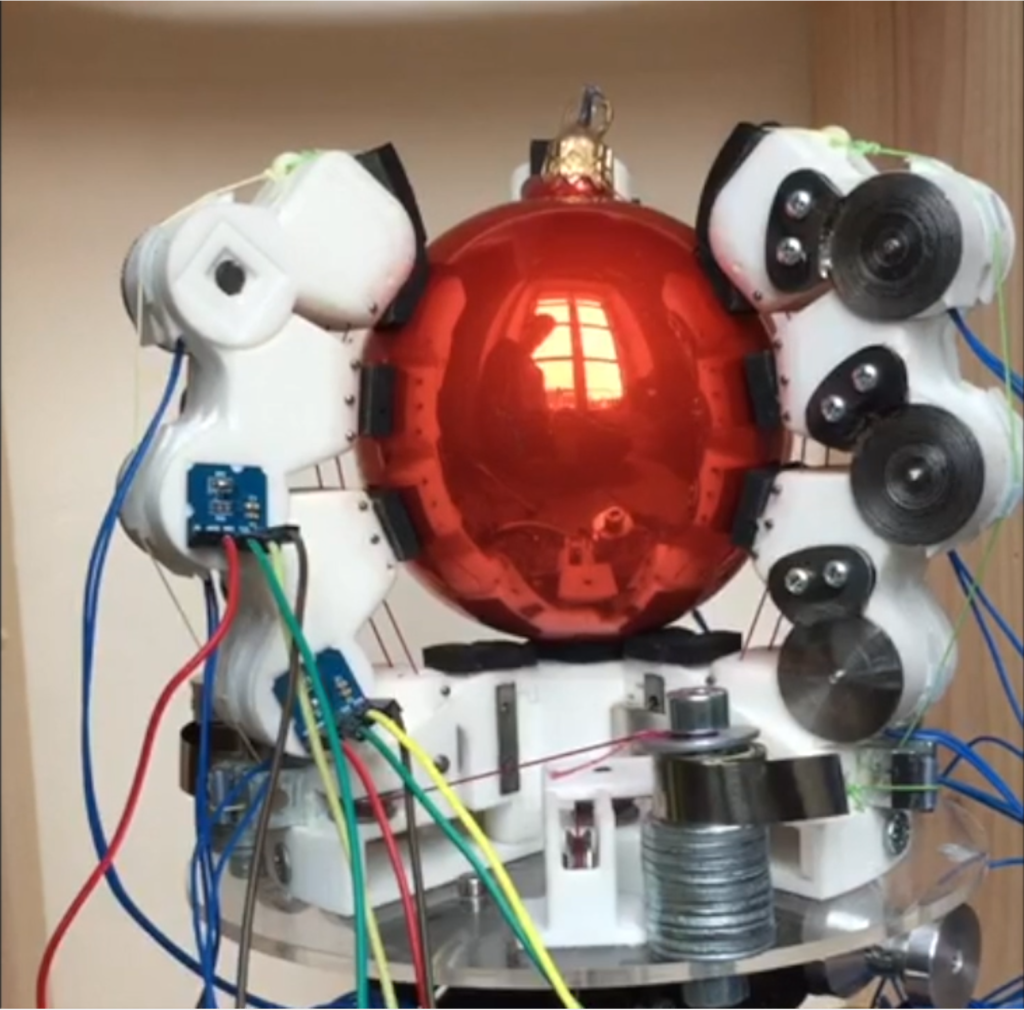

High accuracy and dexterity with a very good grasping performance , high payload capacity of 70N, compact and lightweight actuation unit allows high relevance for industry applications and other mechanical robotic systems.

Concept design – technical requirements

State of the art.

High Payload Capacity = Large & heavy Actuators

Fully Actuated System with many DOF= High # Actuators (DOA)

Compactness + Light Weight

Roboy Project Requirements:

Tendon actuation

Actuation via electrical motors

3D printing and CAD-Modelling

Standard Components

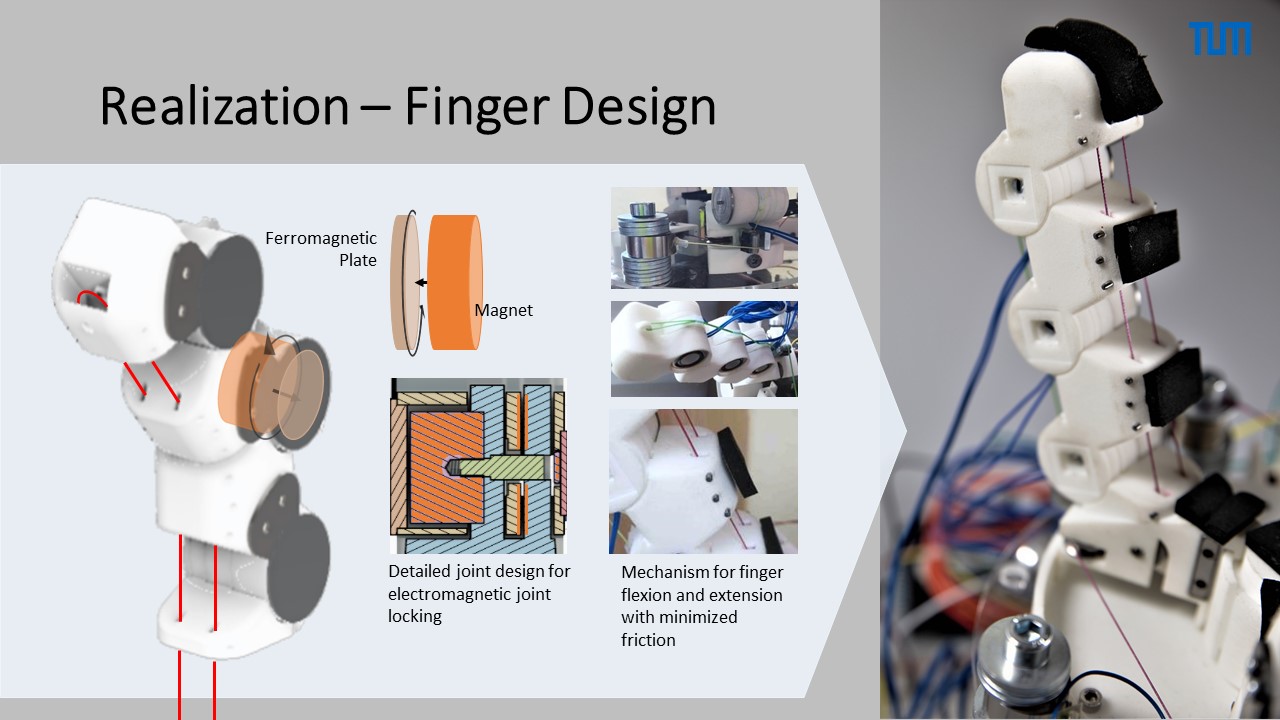

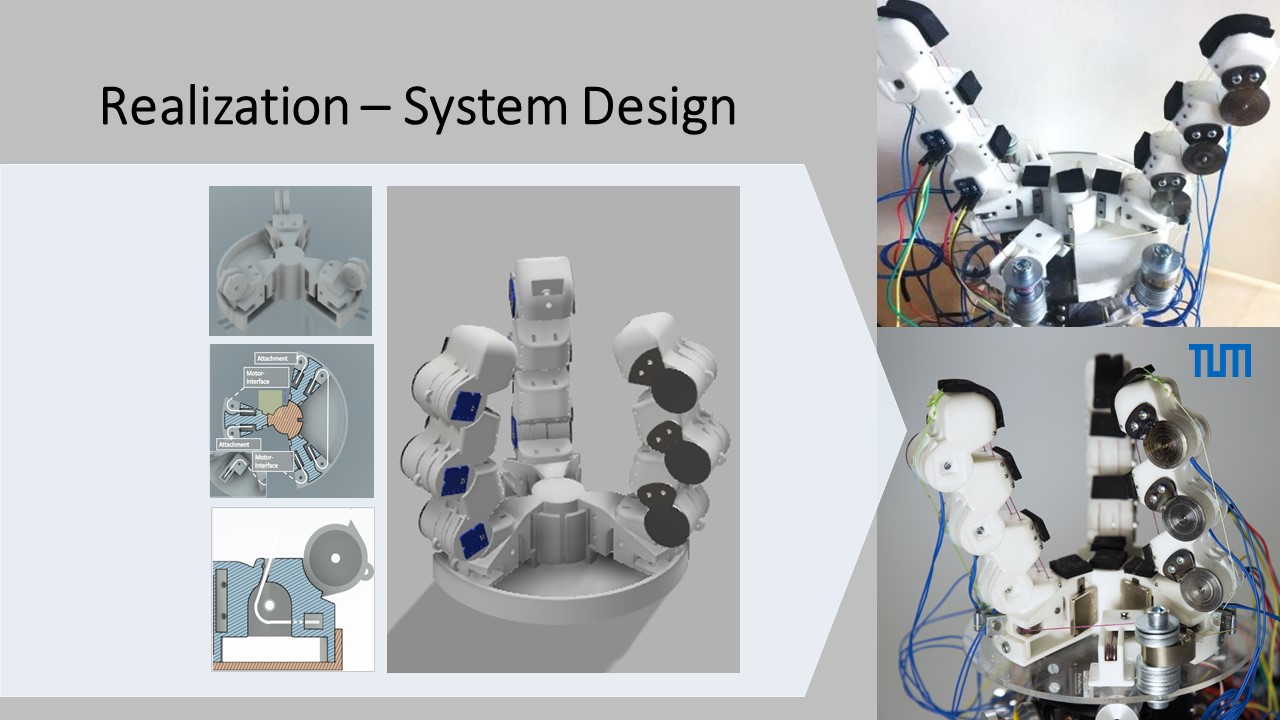

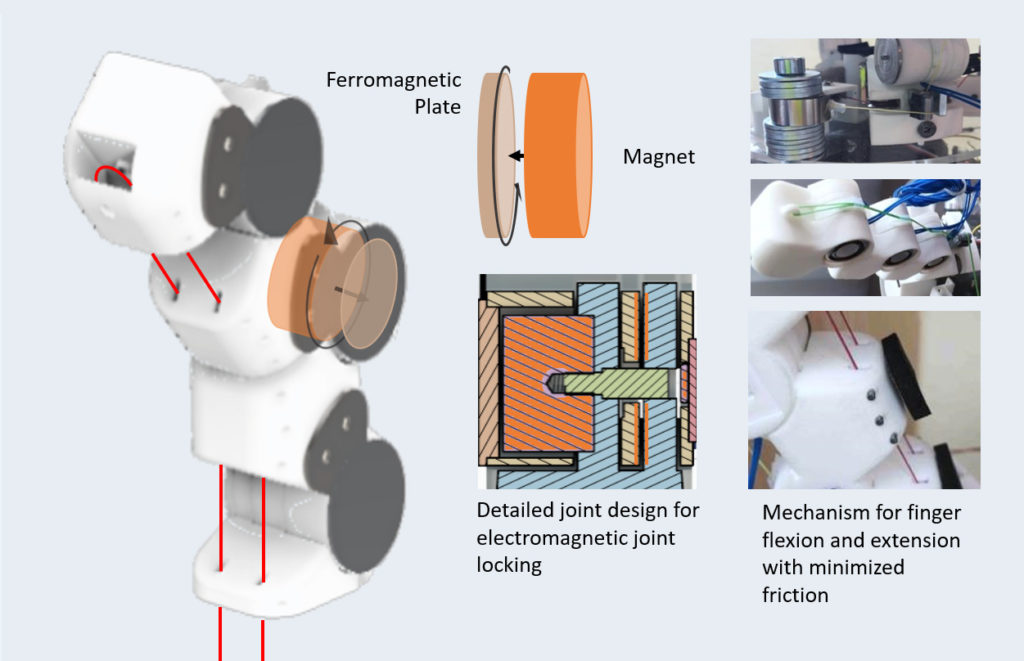

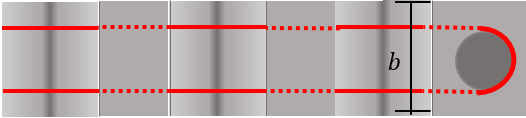

Realization – finger design

Anatomical Purpose:

Grasping oriented functional design-maximization of the force of the hand

Strength to hold things up to 10 kg

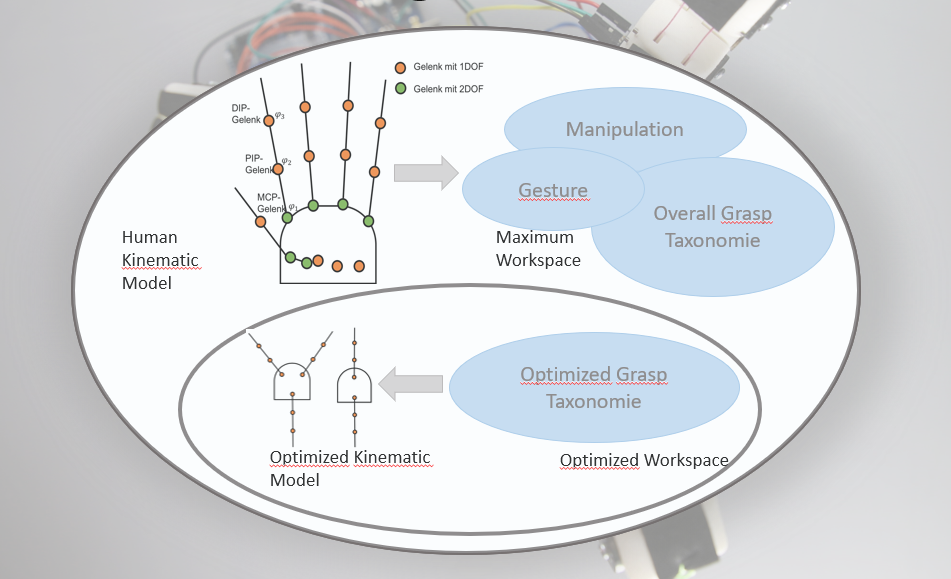

An optimized range of movement (downscaling of the actual 20 DOF in the human hand ) for grasping

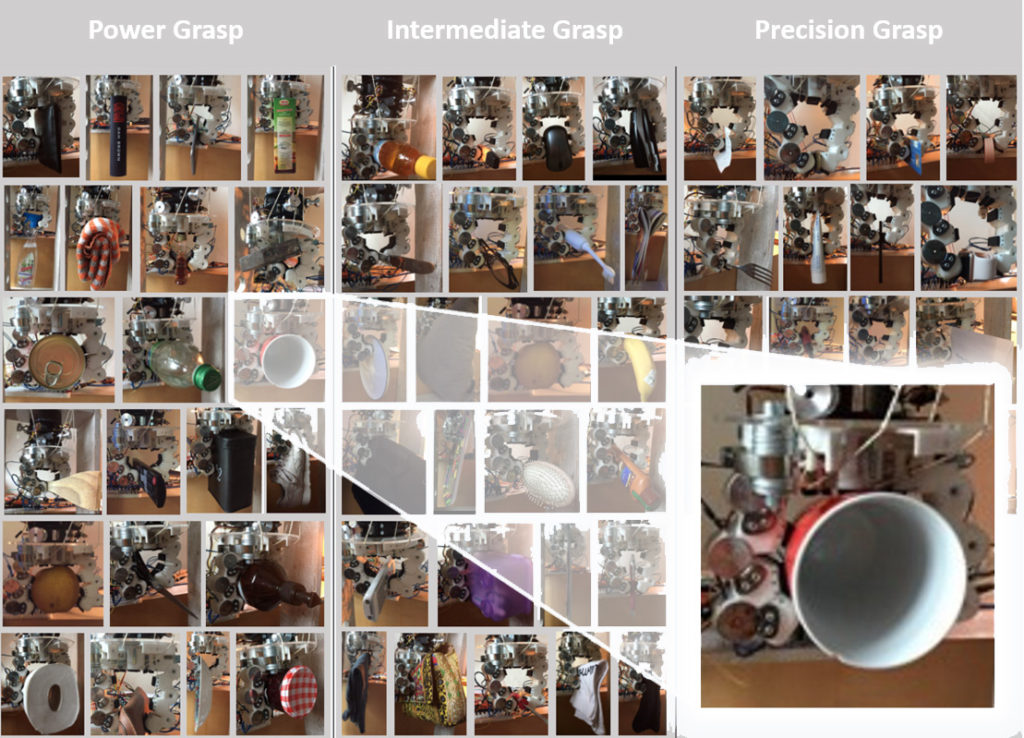

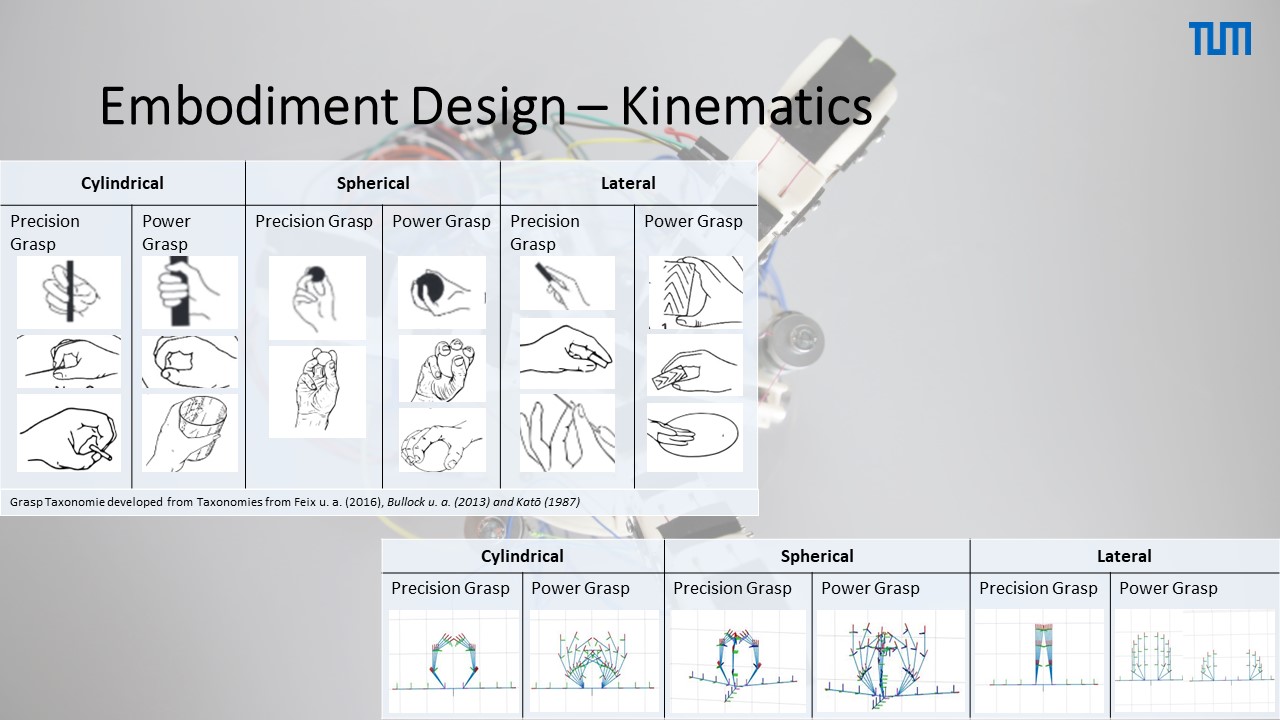

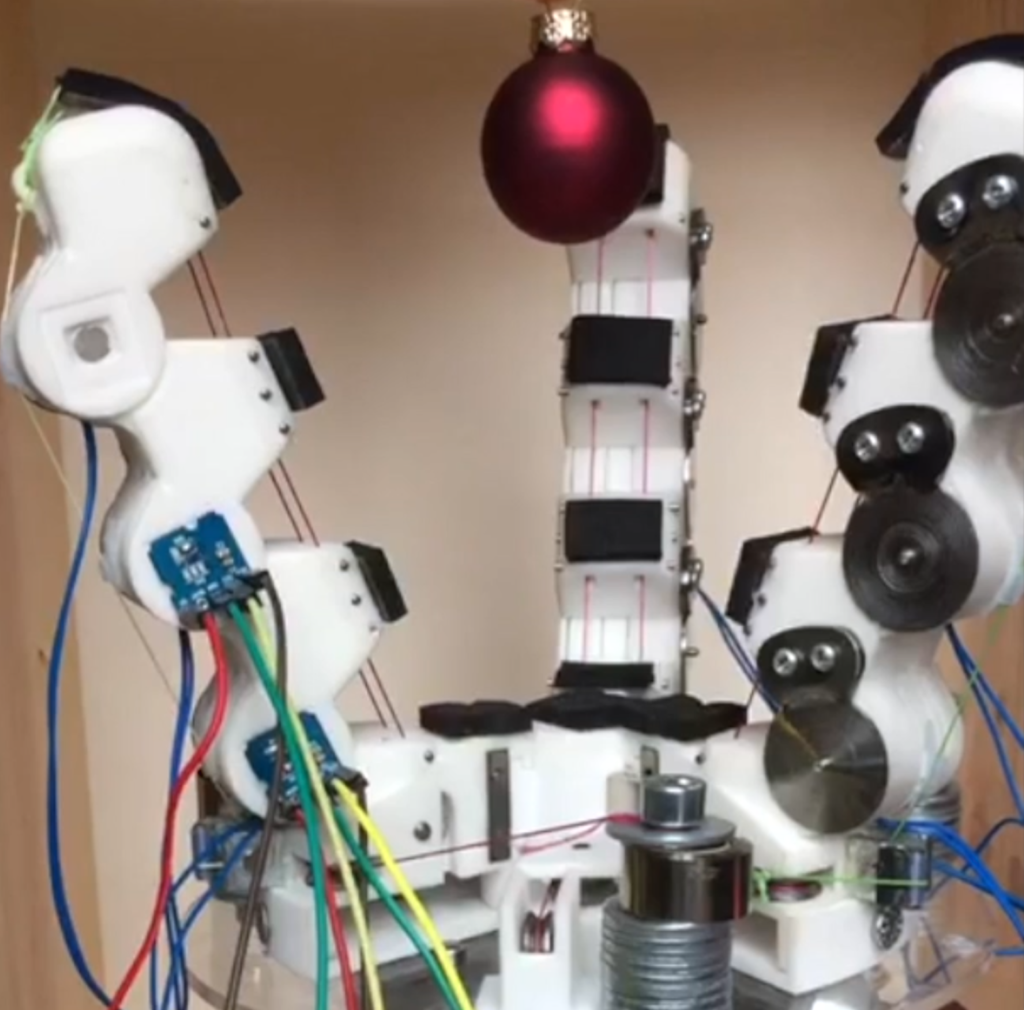

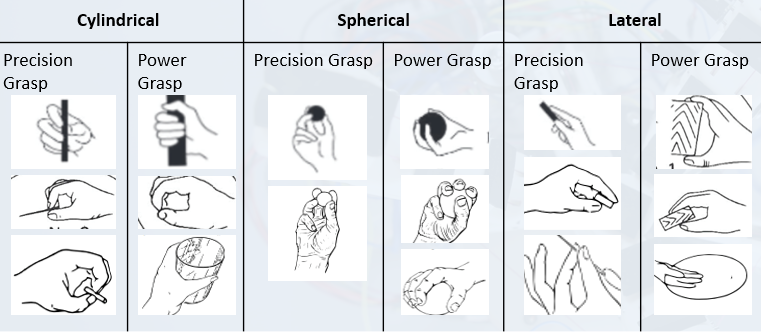

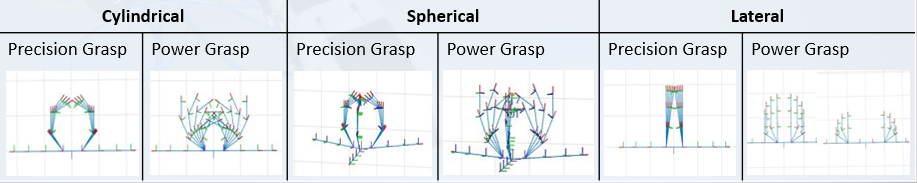

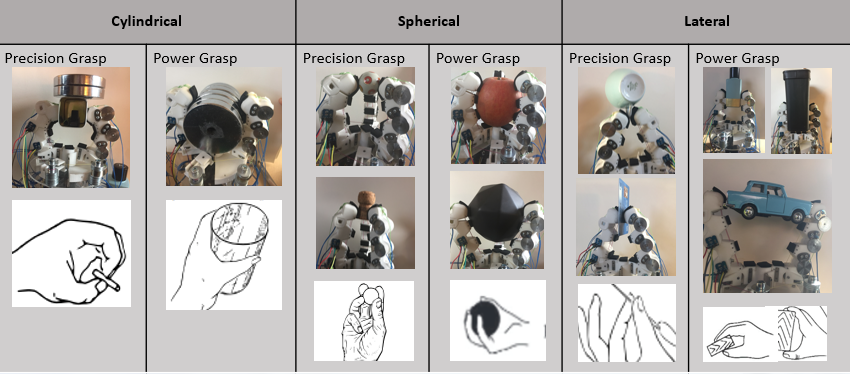

Different configurations of grasping (cylindrical, spherical, lateral) → realization of different ways of grasping

Mechatronic Functionality:

Maximization of the “outcome force of the hand” (a distinction between intrinsic hand forces and hand-wrist force), while minimizing the number of actuators

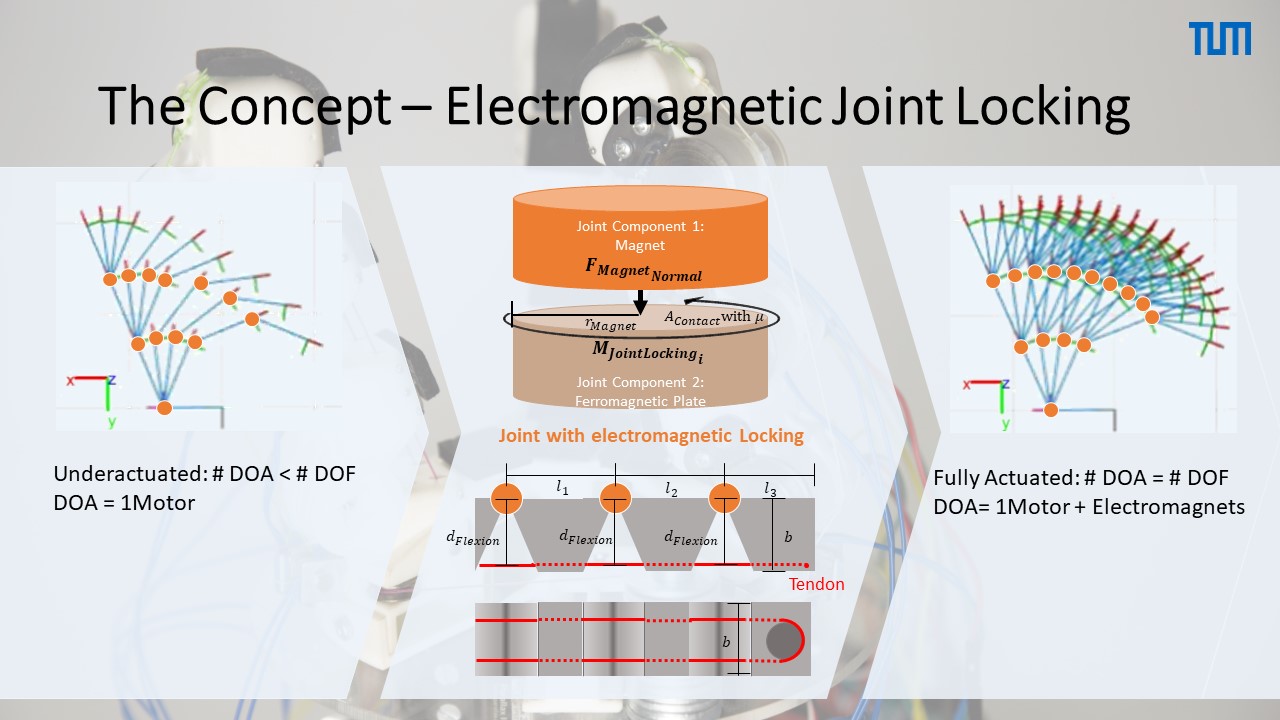

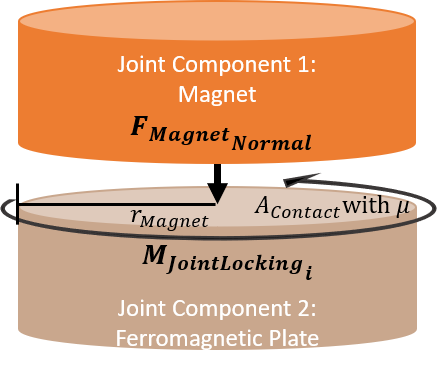

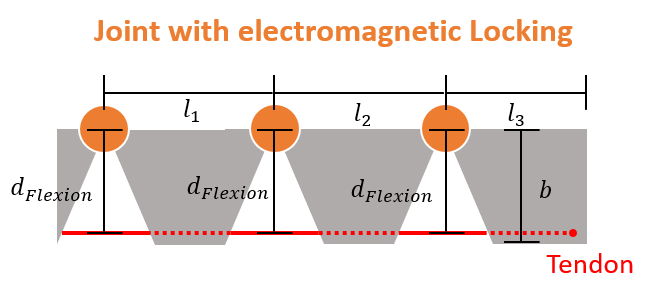

The Concept –

Electromagnetic Joint Locking

DOA = 1Motor

DOA= 1Motor + Electromagnets

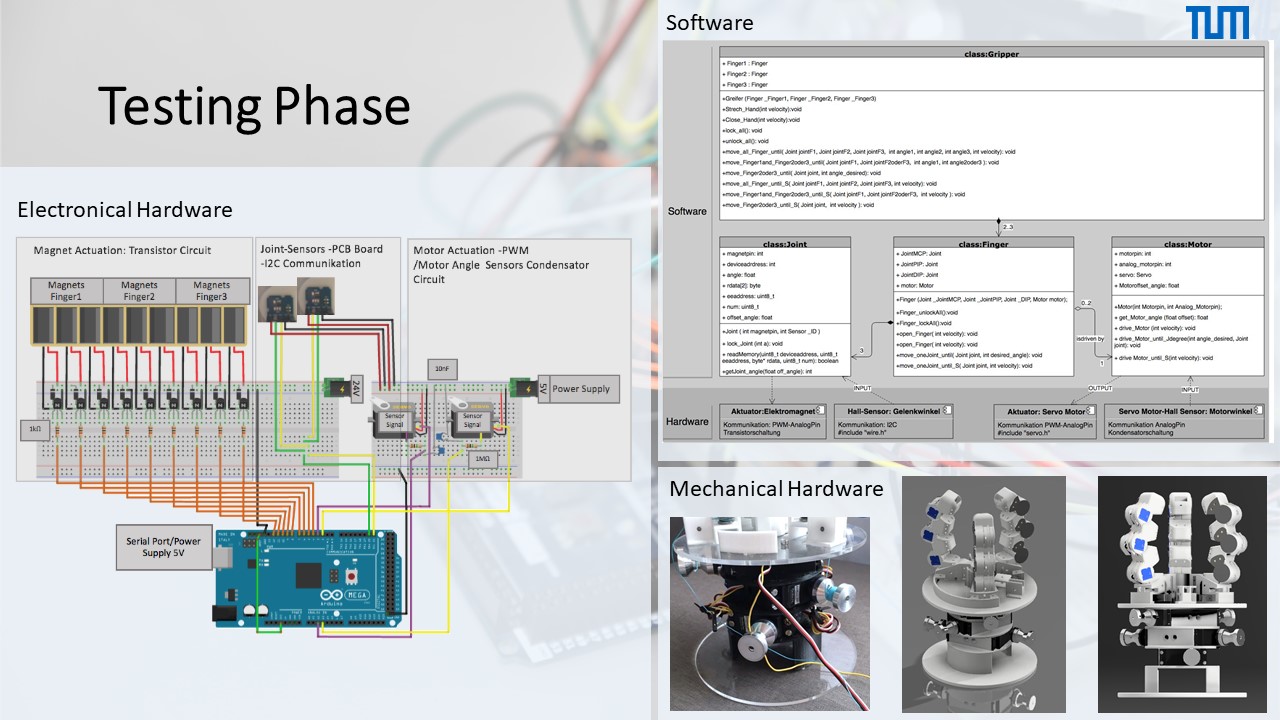

Testing phase

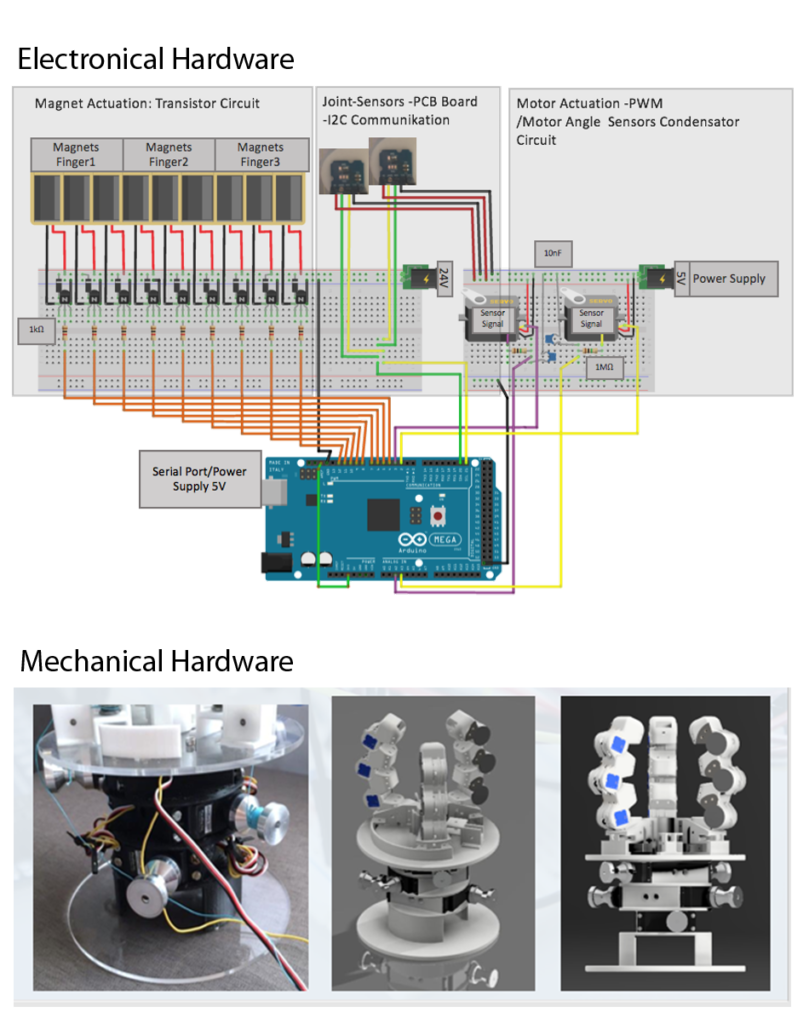

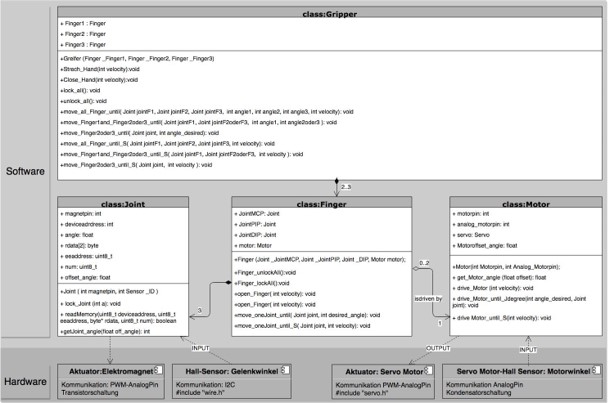

Hardware & Software

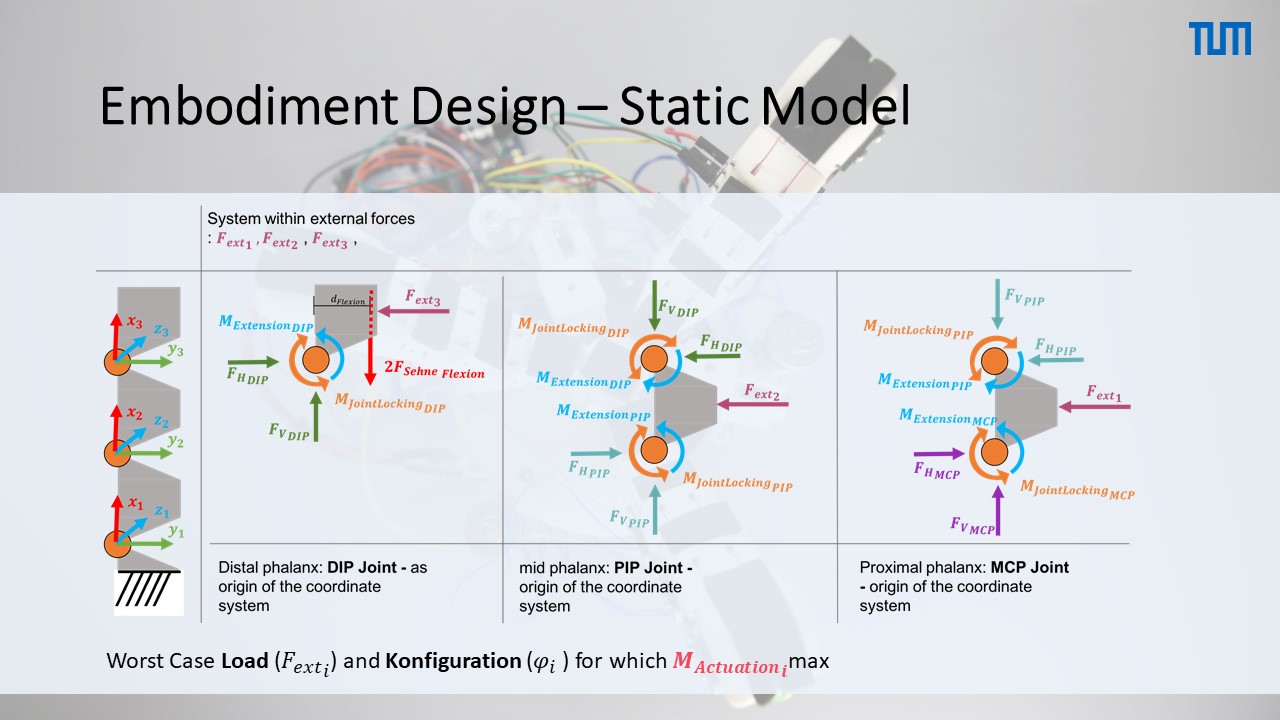

Embodiment Design

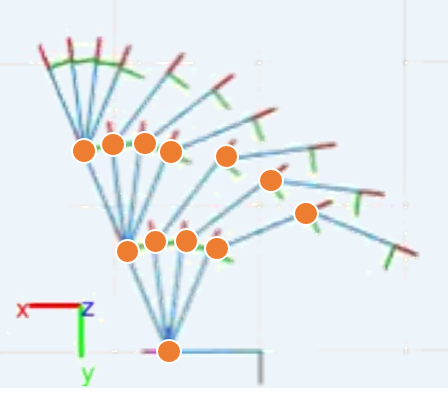

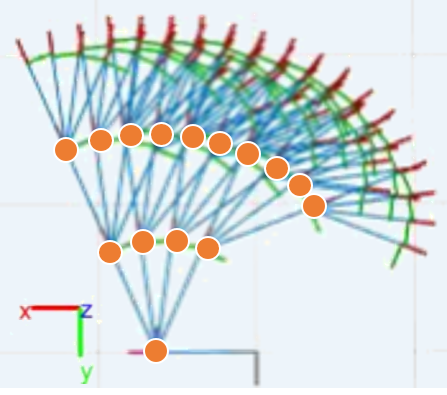

kinematics

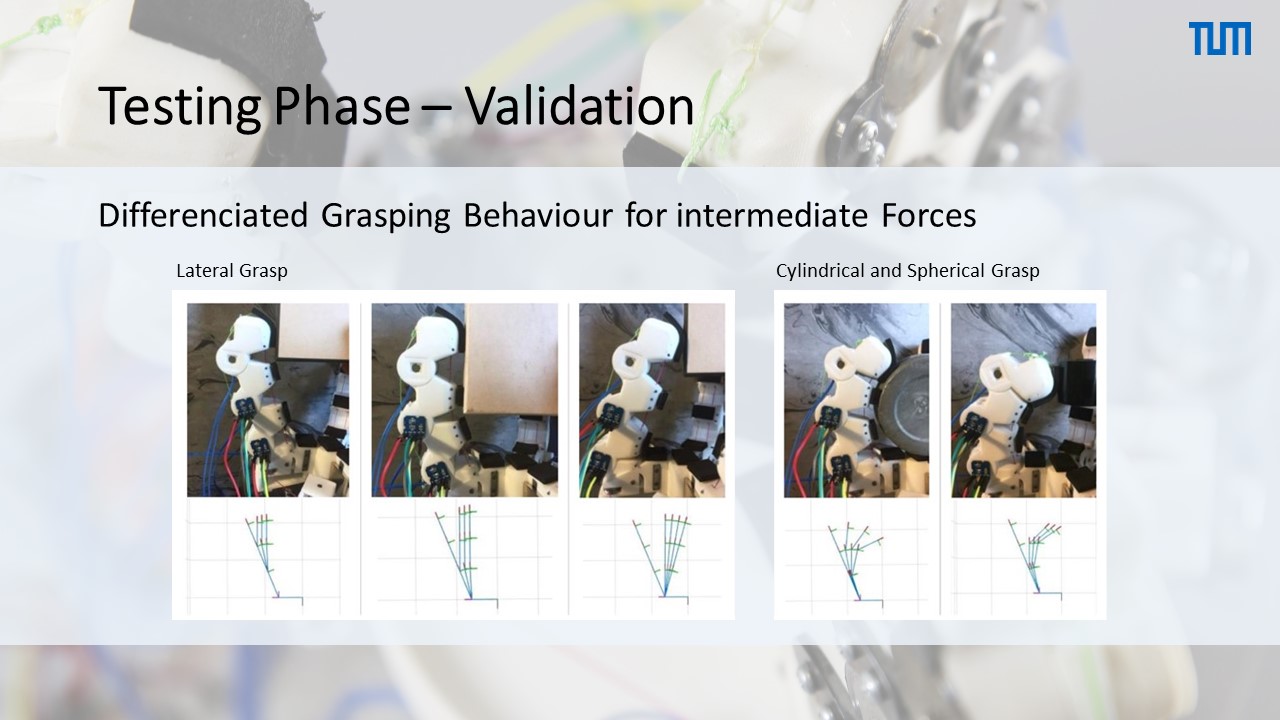

Differentiated Grasping Behavior for intermediate Forces

Test Results – Validation